- Sobre nós

- Áreas de Negócios

- Tecnologias

- Serviços

- Media

- Contato

- Carreira

The first sustainability report is published. At the same time, sustainability management in the Steuler Group is reorganized.

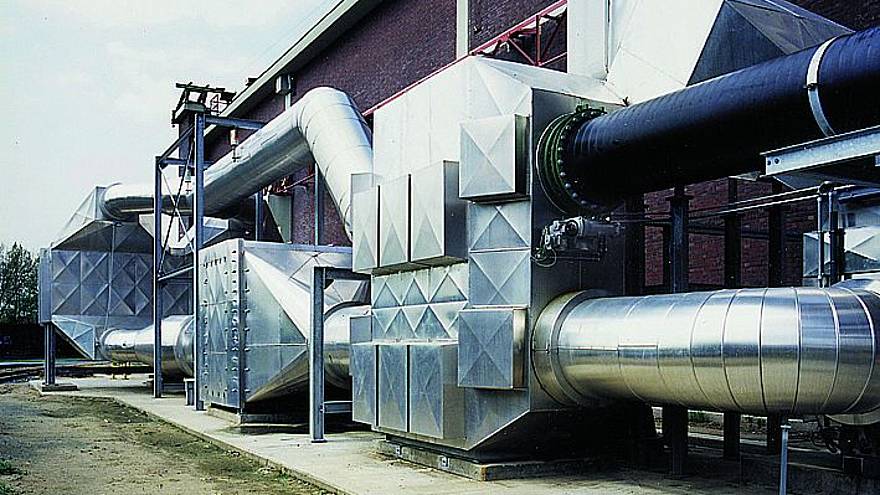

The modular system uses chemical / physical processes to remove the pollutants from the exhaust gas stream and convert them into water, nitrogen and gypsum.

The first wastewater-free pickling plants (ZLD - Zero Liquid Discharge) from Steuler Anlagenbau go into operation in India and China.

Practical training courses and examinations are being held under realistic conditions. With 15 different trades that require formal training and degree courses as well as numerous vocational training courses on offer, Steuler is one of the most sought-after employers in the region.

Steuler-Industriewerke GmbH marks its 100th anniversary to the jubilation of staff and a host of invited guests, all of whom are there to celebrate the success and the solid growth enjoyed by the company over the years.

Steuler Anlagenbau designs the first BIMSchV-compliant wastewater-free flue gas scrubbers (BIMSchV = German Emission Control Ordinance).

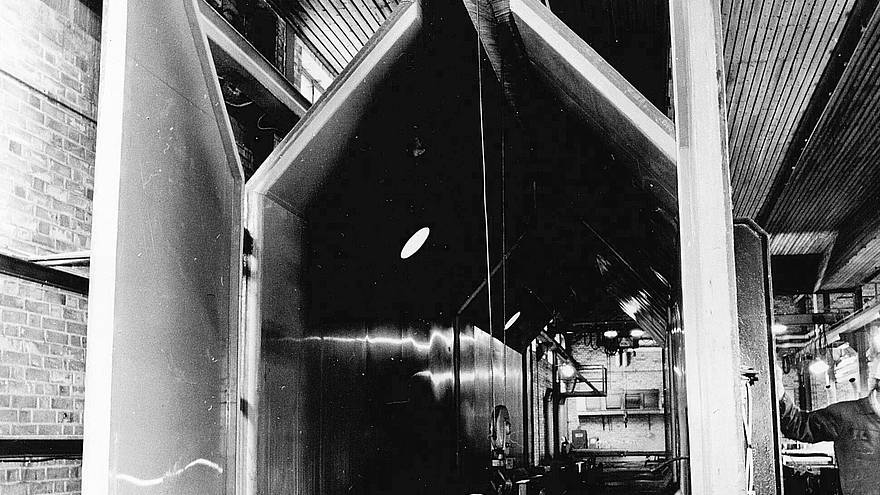

Steuler Anlagenbau engineers develop pioneering membrane technology for wastewater-free pickling plants.

Steuler equipment engineering develops equipment for flue gas DeNOx plants, which splits the hazardous nitrogen oxides into the natural parts of air. Decades before the worldwide discussions about diesel even started.

Steuler Anlagenbau constructs exhaust denitrification plants by using SCR catalysts.

Steuler Anlagenbau is established as a separate division. It is still based in Höhr-Grenzhausen today and undertakes major plant engineering/environmental protection projects around the world.

Founded in 1948, the Georg-Steuler-Support Association helps employees and their families in need, to this day.

Construction of the first company housing for employees on company grounds - a rarity at the time.

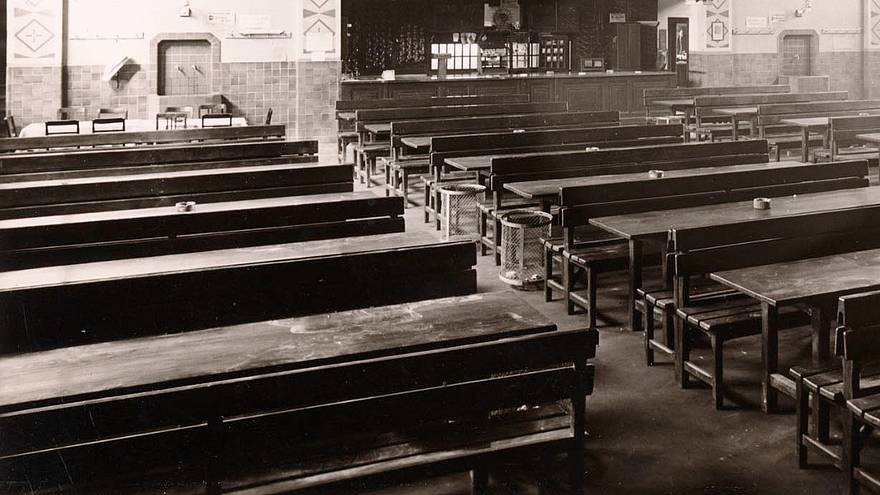

Steuler's concern for the welfare of its employees is apparent from an early stage. A workers' refectory is built in Höhr-Grenzhausen in the same year; the building is still being used as a canteen today.

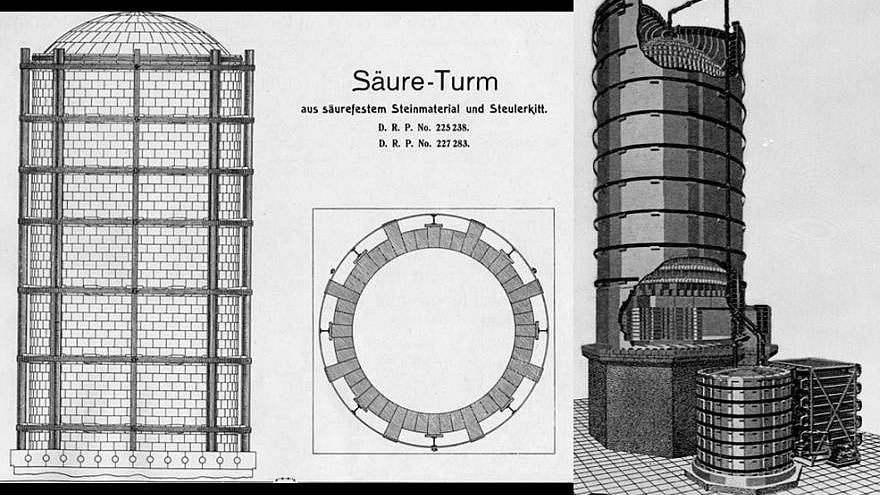

The prototype of an acid-resistant cement enables the industrial scale production in the chemical branch for the first time. Without this invention chemical giants like BASF or Bayer would not exist today.